Titomic awarded $2.325 million MMI grant for space-based applications

Titomic has been awarded a $2.325 million DISER Modern Manufacturing Initiative grant to manufacture and commercialise low carbon emission “green” titanium space vehicle demonstrator parts for the Australian space sector and export markets.

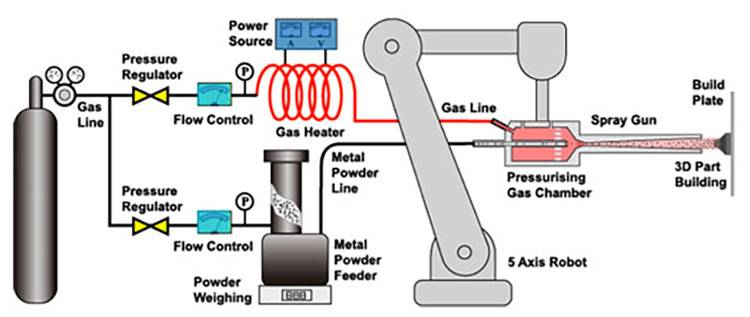

This grant will be part of a planned total eligible project expenditure of $4.65m that will allow Titomic to use its unique Kinetic Fusion cold spray additive manufacturing technology to build and commercialise space vehicle parts using green titanium, heterogeneous material blends, and high-performance coatings for radiation shielding and hypersonic protection.

Titomic, Swinburne University of Technology and the Australian Nuclear Science and Technology Organisation (ANSTO), will conduct extensive testing and validation of demonstrator parts produced within an Industry 4.0 additive manufacturing platform embedded within its Titomic Kinetic Fusion technology. Titomic is teaming with commercial partners, such as Australian sovereign commercial satellite manufacturer Inovor Technologies, to provide specific application use cases and establish performance, testing and acceptance requirements for the technologies.

This additive manufacturing capability will drive high-value technological and material developments, accelerate Space and Manufacturing sector growth, create high-value jobs, and attract investment.

“This $2.325 million Federal Government MMI grant awarded to Titomic showcases our ability to seamlessly integrate our custom Cold Spray Additive Manufacturing

(CSAM) technology systems into partner supply chains, and Joint Venture partners in aerospace with shared risk and reward,” said the CEO of Titomic, Herbert Koeck. “This project allows us to show our unique capability to use industrial scale additive

manufacturing to create world leading “low carbon footprint” green titanium and high-performance coatings for satellites and space vehicles. Our supply of a TKF1000 System to Swinburne University of Technology with its Industry 4.0 additive manufacturing platform to drive high-value technological and material developments, will also accelerate space and manufacturing sector growth in Australia, creating high-value jobs, and attracting local investment.”

“This MMI space-based applications grant … takes the longstanding collaboration between Titomic and Swinburne University of Technology to a new level, building Australia’s reputation as an innovative and high-value space manufacturing nation and we welcome companies and researchers to access this national space manufacturing facility in Victoria, said Professor Alan Duffy, Director of the Institute for Space Technology and Industry at Swinburne University of Technology.